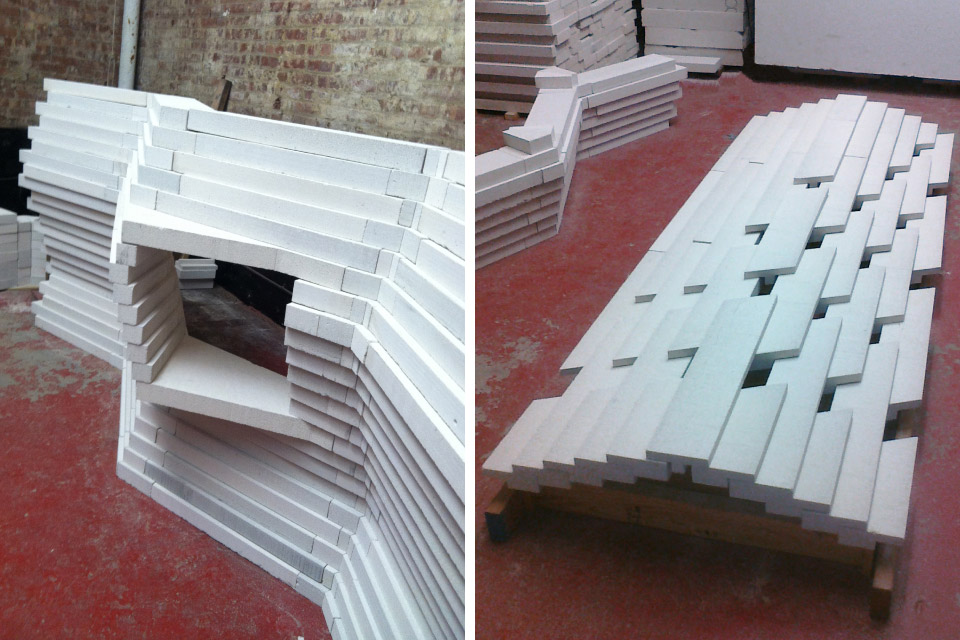

AAC Textile Block

NYSCA Award

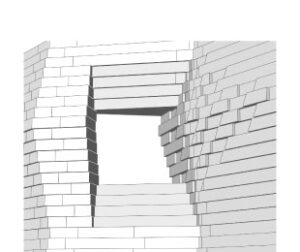

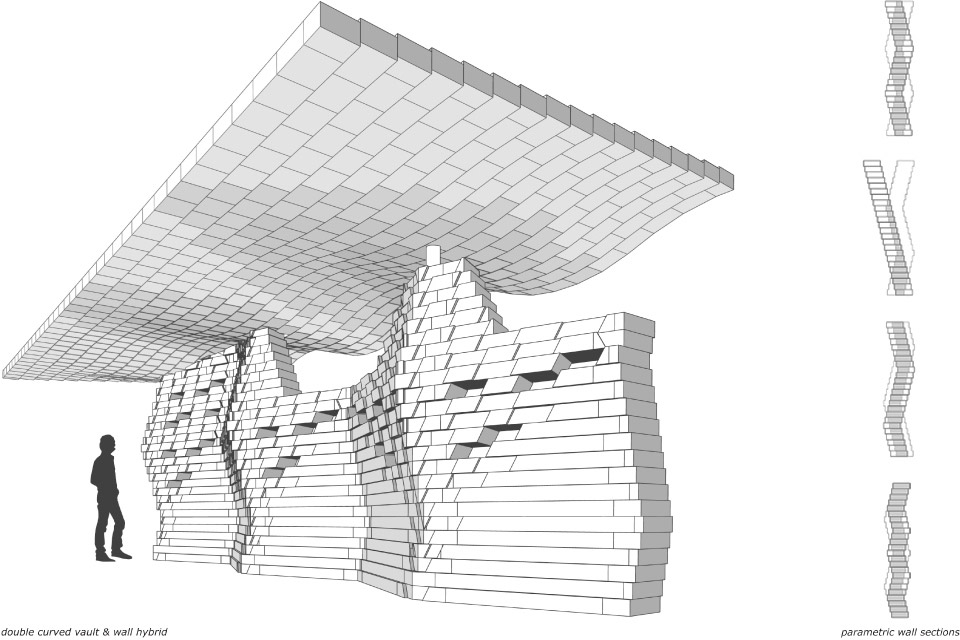

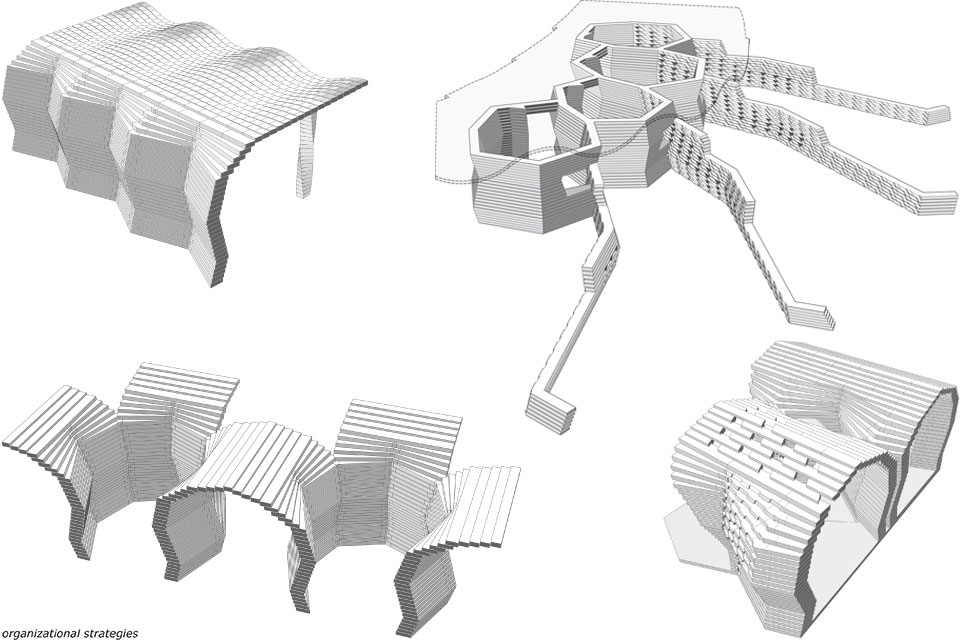

Developed as research funded by a 2010-11 NYSCA Independent Projects Award and Pratt Faculty Development Grant, this work investigates the form finding and structural potentials of Autoclaved Aerated Concrete (AAC) as an integrated wall and vault assembly system. By utilizing traditional masonry corbelling techniques combined with prefabrication, an alternative AAC component logic is designed to produce a novel tectonic. Instead of privileging the flatness of the standard AAC assembly system, the size of the modules and ease of workability of the material can be exploited to quickly construct wall and vault surfaces that are differential and self-supporting.

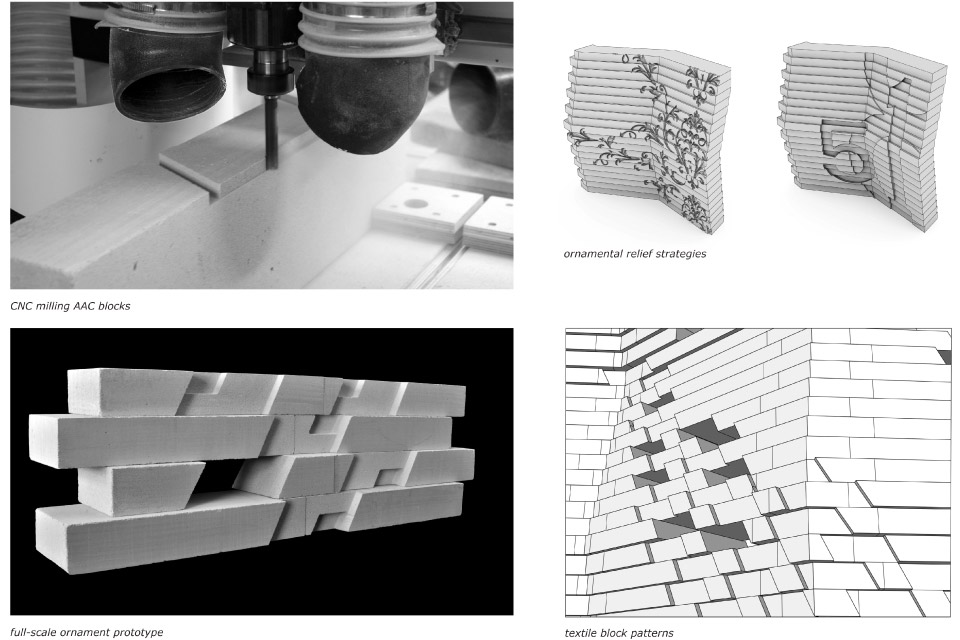

Using a combination of off-the-shelf AAC products and prefabricated custom components milled on a CNC 3-axis machine, complex forms and intricate surfaces can be developed that are easy to build without highly skilled labor. Constructed with a limited set of parts, coded instructions are embedded in the geometry of special joining blocks or “keystones” for ease and speed of erection. Single and double curved vaults can also be produced using precut AAC block types assembled on reusable CNC milled plywood molds. Because the system is non-combustible, insulating, customizable, and requires few additional finishes to produce an efficient envelope, it is well suited for settlement construction following disaster relief.